Products

Packaging Machinery

Products

Packaging Machinery

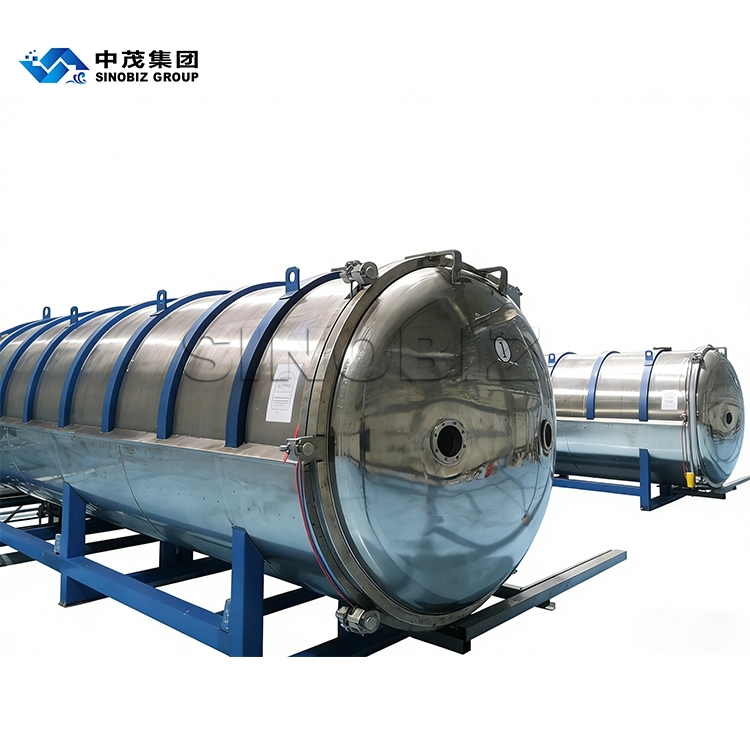

Industrial large-scale LG50 50-square-meter freeze dryer

freeze dryer/ lyophilizer

As a flagship high-capacity solution for large-scale food processing, the LG50 50-square-meter freeze dryer integrates cutting-edge lyophilization technology, robust construction, and intelligent operation—designed to help food manufacturers, agricultural cooperatives, and export enterprises unlock efficiency, preserve quality, and gain competitive edges.

Core Specifications & Build Quality

At its core, the LG50 features a 50㎡ effective drying area, supporting 500–800kg of fresh food per batch (adjustable by product density). Crafted with food-grade 304 stainless steel, it meets FDA and CE certifications, ensuring compliance with global hygiene standards while resisting corrosion and enabling easy sanitization. The insulated drying chamber maintains stable low temperatures (-45℃) and high vacuum levels (1–5 Pa), laying the foundation for superior freeze-drying results.

Key Functions & Operational Efficiency

Equipped with an intelligent PLC touchscreen control system, the LG50 simplifies parameter adjustment—temperature, vacuum degree, drying time, and desorption cycles are precisely configurable, with real-time monitoring to avoid human error. Its three-stage lyophilization process (rapid freezing, sublimation, desorption) preserves the cellular structure of foods, locking in vitamins, minerals, and natural flavors that are often lost in heat drying. The final product achieves ≤3% moisture content, eliminating the need for chemical preservatives.

Practical Roles & Versatility

The LG50 excels across diverse food categories: fruits (strawberries, mangoes), vegetables (spinach, carrots), meats (chicken, beef), seafood (shrimp, fish), herbs, and dairy products. It transforms fresh ingredients into shelf-stable, ready-to-eat or rehydratable products—ideal for healthy snacks, baby food, emergency rations, or export-grade goods. By reducing product weight by 70–90%, it drastically cuts storage and transportation costs, a critical advantage for global trade.

Competitive Advantages & Value Proposition

Compared to traditional drying methods, the LG50 offers unmatched benefits: no nutrient degradation, no texture hardening, and 100% additive-free outputs that align with modern consumers’ demand for healthy food. Its high throughput meets large-scale production needs, while low energy consumption and durable build reduce long-term operational costs. For businesses, this translates to expanded product lines, higher profit margins, and access to premium markets that prioritize quality and safety.

Decision-Making Guide

If you’re scaling up food production, targeting export markets, or aiming to replace outdated drying equipment, the LG50 delivers immediate value: it solves the pain points of short shelf life, high logistics costs, and compromised quality. Backed by reliable performance and global certifications, it’s a low-risk investment that drives sustainable growth in the competitive food industry.

5.0

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

Please fill out the form below to request a quote or to request more information about us. please be as detailed as possible in your message, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

Model

LG50

Turnkey Solution for Freeze Drying Equipment – Industrial-Grade Freeze Dryer (Lyophilizer)

This Food (Fruit & Vegetable) Freeze Dryer (Lyophilizer) is designed for the freeze-drying of more than 20 categories of food products, including meats, vegetables, fruits, aquatic products, legumes, beverages, soups, and health supplements. Its processed products meet the requirements of being natural, nutritious and easy to consume.

12 (6)

18 (3)

Product features

- Split structure for pre-freezing and drying processes, which can be operated simultaneously to improve freeze-drying efficiency and shorten processing time.

- Aerospace-grade aluminum alloy partition plates with double-sided radiant heating, achieving a radiation rate of over 90% and excellent temperature uniformity.

- High-efficiency hybrid refrigerant carrier medium features a low freezing point and high boiling point, ensuring high heat exchange efficiency and a long service life.

- Optimized control algorithm for drying curves enables precise control over product heating rate and vacuum level during the drying phase.

- Professional gas flow guiding design and control technology deliver strong water trapping capacity and high drying efficiency.

- Trays are stamped from aviation anti-rust aluminum alloy and undergo special surface treatment for high heat absorption rate. Each drying chamber is equipped with 2 sets of material-holding trays.

- Industrial-grade embedded touch screen combined with a dedicated SH-HPSC-III modular controller ensures stable, reliable system operation and high control precision.

- Application Scope of Food (Fruit & Vegetable) Freeze Dryer

- Chinese Herbal & Health Supplements: Ginseng, gastrodia elata, panax notoginseng, wolfberry, fleece-flower root, dendrobium officinale, cordyceps, bird's nest, bee products, deer products, etc.

- Various Extract Preparations: Anthocyanins, ginkgo biloba extract, nutrient solutions, biological preparations, reagents, enzymes, antibiotics, etc.

- Aquatic Products, Meats, Poultry & Eggs: Sea cucumbers, abalones, shellfish, shrimp, fish, beef and mutton, chicken, egg products, etc.

- Forest By-products: Edible fungi, wild vegetables, matsutake, dictyophora, asparagus, momordica grosvenorii, snake meat, forest frogs, pollen, konjac, etc.

- Fruits, Vegetables & Soup Mixes: Various fruits (strawberries, raspberries, mangoes, lemons, apples, peaches, etc.); various vegetables (green onions, garlic, Chinese yam, purple sweet potatoes, etc.); various instant soup mixes and beverages (egg drop soup, seaweed soup, seafood soup, tomato soup, coffee, orange juice, tomato juice, etc.).

Main technical parameters

|

Type |

LG50 |

|

Effective area of shelves |

56m2 |

|

Input capacity |

500L/batch (10mm) 1000L/batch (20mm) |

|

Maximum Condenser capacity |

800Kg/batch |

|

Power supply |

380V/50Hz 3Ph+N+PE |

|

Installed power |

120Kw |

|

Cooling method |

Water-cooled |

|

Weight |

About 30000Kg |

{{scoreAvg}}

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Get in touch with us

Just leave your email or phone number in the contact form so we can send you a free quote for our wide range of designs!

Related Products

no data

+86 13354196886

Ly Sinobiz Machinery Co., Ltd.

Welcome to LY SINOBIZ MACHINERY CO., LTD- a world-leading health care product machinery and pharmaceutical packaging machinery technology enterprise committed to innovation, excellence and sustainable development. Our mission is to make the world a better place through our technology and services.

Shortcut links

Contact with us

Contact Person: Long Yang

Contact Number: +8613354196886

Email: davidhe@lyzw.cc

WhatsApp: +8613354196886

Company Address: Xiexi Industry Zone, Liaoyang City, Liaoning Province