Automatic Heat-shrink Wrapping Machine sealing function BTA-450A

This machine is suitable for large-volume shrink packaging in food, supplement, cosmetic, stationery and other industries. The machine adopts famous brand PLC automatic program control, easy to operate, with safety protection and alarm functions, effectively preventing miscuting the products. Equipped with imported horizontal and vertical detection photoelectric, which is convenient for switching and selection.

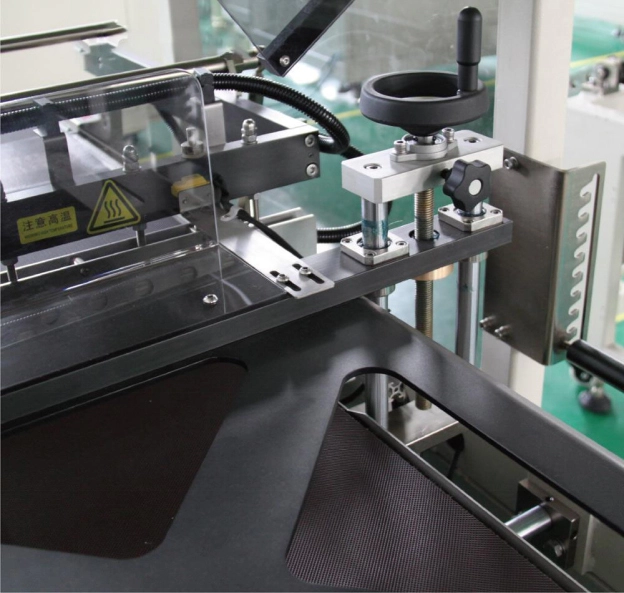

BTA-450A also has a sealing function, which is specially designed for packaging small products. The whole set of machines can realize unmanned operation connection with the production line.

Features

This machine is a fully automatic L-shaped sealing and shrinking packaging equipment, which can be connected to various fully automatic packaging lines.

The built-in Omron PLC programmable controller has safety protection and fault alarm functions, which improves the operation stability of the machine.

The sealing knife adopts American DuPont Teflon anti-stick coating, the sealing will not crack or burn; the sealing knife has an automatic protection function to prevent miscutting the package.

By adjusting the height of the film guiding device and the feeding and conveying platform, products of different widths and heights can be packaged without changing the mold and bag maker.

Features

Automatic feeding, the length of the bag is automatically controlled by the combination of electric eye and timer; equipped with a waste induction motor, which can automatically roll up the waste edge.

Equipped with an independent and movable pinhole deflation device to make the packaging effect more beautiful.

Equipped with American Banner brand detection photoelectric eyes, one set of horizontal and vertical detection, switching options can pack thinner and smaller items.

Omron digital display temperature controller is adopted, the temperature can be set freely, and the sealing and cutting temperature is extremely sensitive and accurate.

Sample photo

Detail photos

Technical parameters

|

Items |

Parameters |

|

|

Model |

BTA-450A Wrapping Machine |

BM-500 Heat-shrink Tunnel |

|

Max. packing size |

(L+W) ≤ 200 inch (500 mm), |

(L) 280 inch (700 mm), |

|

Max. sealing size |

(L) ≤ 220 inch (550 mm), |

(L) ≤400 inch (1000 mm), |

|

Packing speed |

900-1800 pcs/h (15-30 pcs/min) |

0-15 meters/min |

|

Power Supply |

1phase, 110/220V, 50/60Hz, 1.3kw |

3phase, 220/380V, 50/60Hz, 12kw |

|

Air pressure |

5.5kg/cm3 |

/ |

|

Overall dimension |

(L)1800×(W)800×(H)1600mm |

(L)1300×(W)700×(H)1400mm |

|

Weight |

440kg |

240kg |

Configuration list

|

Name |

Brand |

QTY |

Remarks |

|

Feed Conveyor Motor |

ZHONGDA |

1 |

|

|

Outfeed Conveying Motor |

ZHONGDA |

1 |

|

|

Film Pulling Motor |

ZHONGDA |

1 |

|

|

Film Feeding Motor |

ZHONGDA |

1 |

|

|

Scrap Recycling Motors |

ZHONGDA |

1 |

|

|

Master Cylinder |

SHAKO |

1 |

|

|

Tight Cylinder |

SHAKO |

1 |

|

|

Breaker |

SCHNEIDER (FRANCE) |

2 |

|

|

PLC Programmable Controller |

TAISONG |

1 |

|

|

Temperature Controller |

OMRON (JAPAN) |

2 |

|

|

Time Relay |

OMRON (JAPAN) |

3 |

|

|

Intermediate Relay |

OMRON (JAPAN) |

7 |

|

|

Solid State Relay |

OMRON (JAPAN) |

2 |

|

|

Material Up and Down Sensor Switch |

BANNER (USA) |

2 |

|

|

Material Left and Right Sensor Switch |

BANNER (USA) |

2 |

|

|

Cylinder Solenoid Valve |

SHAKO |

2 |

|

|

Air Filter |

SHAKO |

1 |

|

|

Proximity Switch |

DELIXI |

1 |

|

|

Conveyor |

|

2 |

|

|

Timing Belt |

|

2 |

|

|

Sealing Knife |

|

2 |

DuPont(USA) |

Packing & Shipping

SINOBIZ Customer

Product video