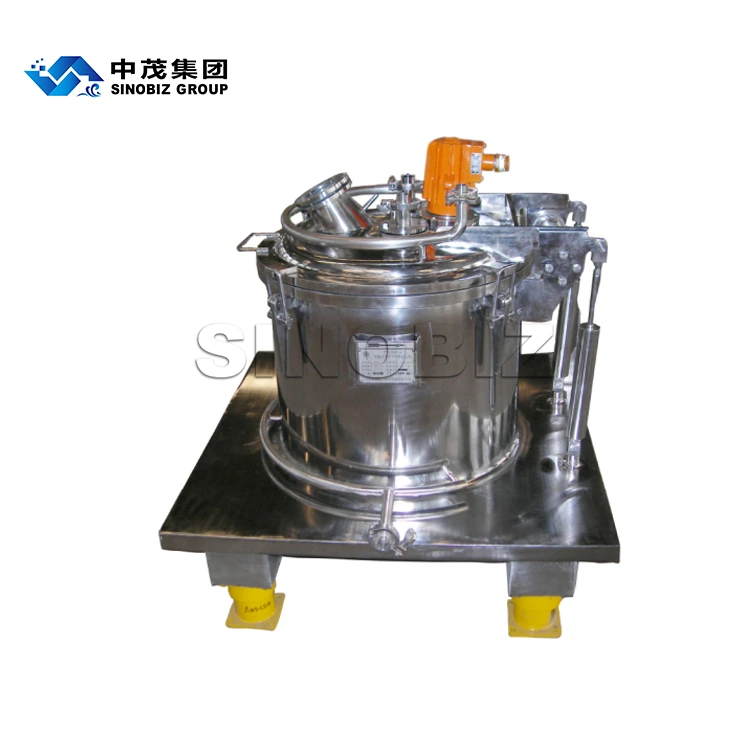

Flat type direct connection top discharge centrifuge

This product stands out for its outstanding quality and leading-edge technology, having successfully obtained EU CE certification and UK UKCA certification, while also strictly complying with ISO international standard systems and GMP Good Manufacturing Practice (GMP) certification. The endorsement of these authoritative certifications not only demonstrates that the product meets world-class standards in terms of safety performance, quality control, and production processes, but also reflects our unwavering commitment to excellence in quality.

Since its launch, the product has been successfully supplied to customers in over 100 countries and regions worldwide, serving a wide range of sectors including industrial manufacturing, healthcare, and daily consumer goods. With its stable and reliable performance, superior technical advantages, and comprehensive after-sales service, the product has earned widespread praise and high recognition from customers both at home and abroad. Extensive real-world user feedback and long-term partnerships are a strong testament to its exceptional quality and proven reliability, making it a trusted and dependable choice you can rely on.

Product Introduction

PSL model flat type direct connectioncentrifuge is designed based on GMPstandard and environmental protectionsanitary requirement, it is a fully closed manualtop discharge centrifuge.

It is equipped with bigflip closed shell, cancelled traditional suspension support leg, and adopts flat platebalance weight and high viscosity dampvibration isolator without base install. Invertercontrol the motor, it connects directly with thedrum through the motor spindle,which makes thedrum rotating high speed around itself axis to formcentrifugal force field, then the centrifuge forcepushed the material equispaced on the drum toseparate the solid and the liquid.

The liquidpenetrates the solid and the fiter screen gap,then was tossed to the main case space, anddischarged from the bottom liquid outlet,the solidmaterial will hold back in the drum,and will bemanually discharge from the top when themachine shutting down.

main features

1.Simple construction,rational design,

convenient operating maintenance.Dynamicbraking,without vulnerable parts like beltbrake,ete,and without friction dust pollution,itis very suitable for the strict environmentrequirement in GMP standard.

2.With big turnover coverconvenientdischarge.Thefixing parts and drum of it arewith polished surface It is easy to clean thegap between the shelland the drum.

3.Closed construction,sealing parts adoptssilicone rubber and fluororubber to satisfyclosed anti-explosion requirement,it is suitablefor the poisonous,inflammable and explosivescene.

technical parameters

main application

It is suitable to the suspension liquid with micron grade solid granular,crystal and threadinessparticles or a whole material.It is widely used in pharmacy, food, chemistry, light industry, environmental protection industry, etc.

standard configuration

1.Controlled by the inverter with smoothand steady start,the separation factor isadjustable, to achieve the charge andwashing rotating speed differ.

2.Adopted high viscosity liquid dampingvibration isolator to erase the vibrationeffectively and easy to maintenance.

3.Equipped with cleaning spray system, andcan achieve the online cleaning for thecentrifuge, and the internal shell, drum inner andouter surface,liquid collector surface and someinvisible parts inside the centrifuge conformed tothe GMP requirement!

4.Equipped with nitrogen protection system,to make sure the inside and the outside air notcontact.

5.Widely used, and the crystal is not easy tobreak.

outline and installation size