High-Speed Wet Granulator Stainless Steel Agitator Wet Granulation Drying Equipment Granulator Machine

GHL Wet Granulating Machine

Product Description

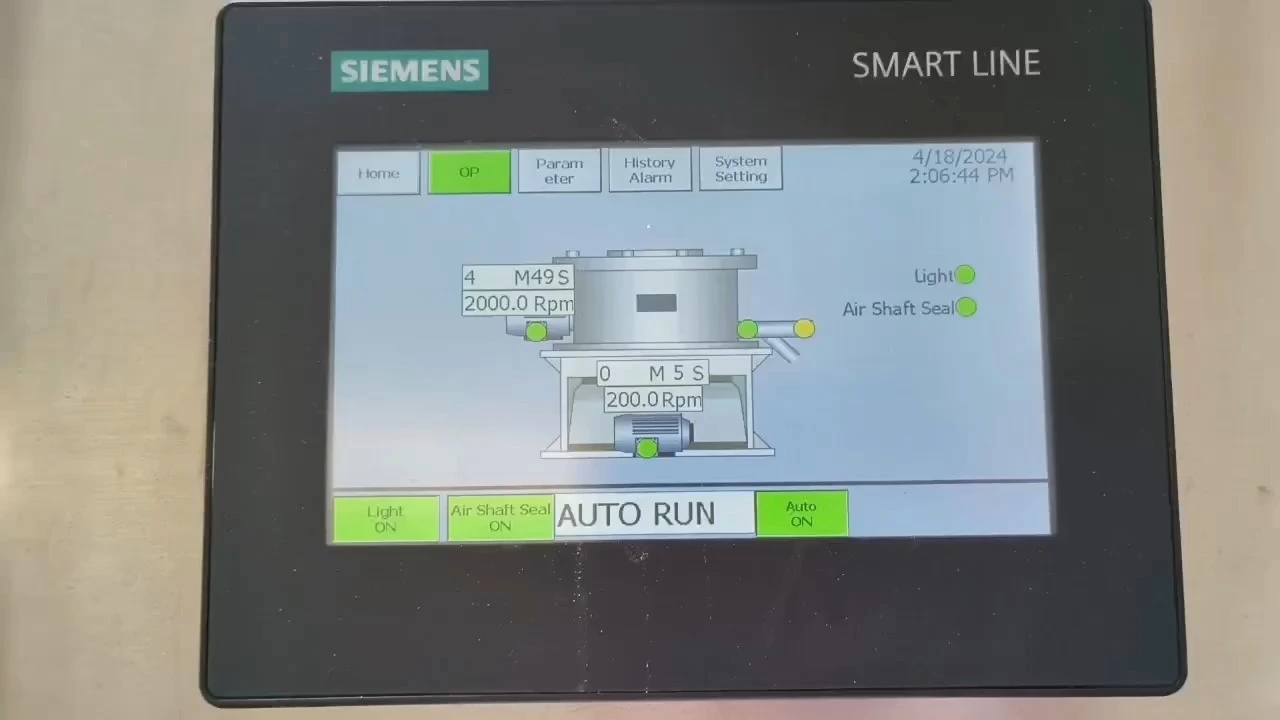

Designed to comply with GMP (Good Manufacturing Practice) standards, the wet granulator is typically constructed with pharmaceutical-grade stainless steel (e.g., 304/316L) for all parts that come into contact with materials. This ensures excellent corrosion resistance, easy cleaning, and zero cross-contamination risks. Additionally, the equipment is equipped with intelligent control systems that allow for precise setting and monitoring of process parameters, guaranteeing consistent batch-to-batch product quality. Its advantages of high granulation efficiency, uniform particle size, and gentle material handling make it an indispensable piece of equipment in modern solid preparation production lines.

Product Specifications

| Volume of Container | 15L |

| Capacity | 5KG/batch |

| Mixing speed | 0-270 rpm |

| Mixing power | 2.2KW |

| Cutting speed | 0-2990 rpm |

| CUtting power | 1.1KW |

| Pressure of compressed air | 0.4-0.6Mpa |

| Consumption of compressed air | 0.1m³/min |

| Dimension | 1200*600*1100mm |

Product Features

Machine Details

Product Application

The mixing system drives the materials to undergo three-dimensional movement, ensuring that the adhesive fully coats each powder particle, which in turn transforms the dry powder into a homogeneous, humid soft mass with appropriate viscosity and moisture content.

FAQ

Tell us about your project requirements and we will figure out a solution that will meet your budget and design expectations.