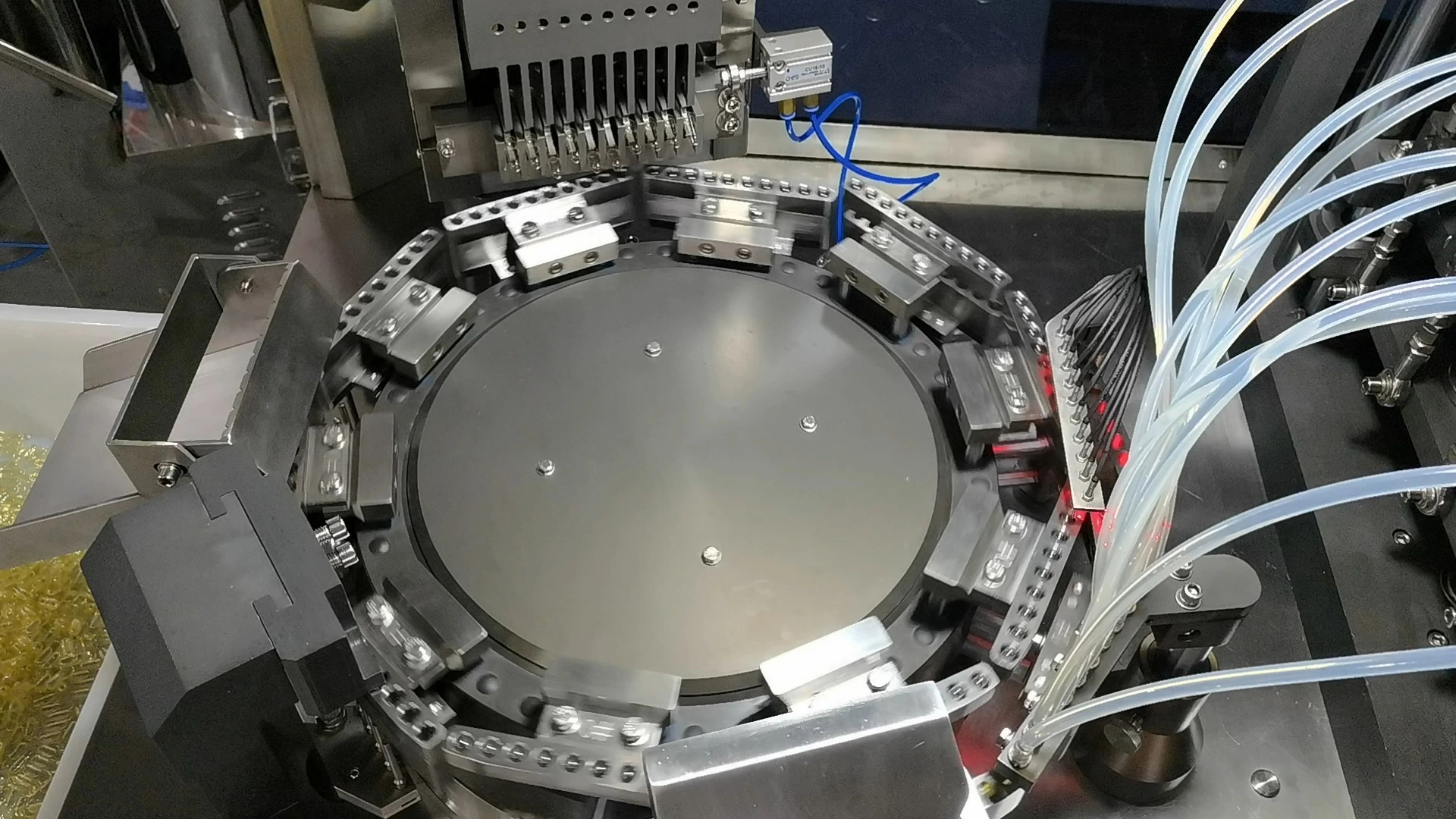

NY-600 Hard Capsule Liquid Filling Machine

NY-600 hard capsule filling machine is a device designed and produced by our company. It can be filled in a hard capsule (solution, suspension, microemulsion). The ceramic pump is used to add liquid, and the servo motor controls the loading system to ensure the difference in loading, accurate measurement, fiber inspection, lack of glue, and automatic kicking.

performance overview:

This machine adopts the stepless frequency converter, which is convenient and intuitive to operate. As a new and convenient mode of administration and filling concept in the new century, this machine is the latest filling equipment for developing high-end products in the pharmaceutical, health care and other industries.

Product features

1. The equipment adopts man-machine interface control system, which automatically lacks capsules and lacks material alarm.

2. The capsule feeding machine has a vacuum positioning and separating mechanism, so that the probability of the capsule is over 99%. The fiber is automatically detected, and the capsule is missing in the upper and lower mold holes.

3. High-precision ceramic pump and servo motor dosing system are adopted to control the difference of the loading amount to about ±2%, and the dosage is accurate.

High precision ceramic pump

The liquid filling mechanism adopts a high-precision ceramic pump and a servo motor dosing system to control the difference in liquid material loading in the capsule to about ±2%, and the measurement is accurate.

Capsule sowing

The new pod rack adopts a rail-type transmission mechanism, which has high running precision and long service life. The closed design eliminates the entry of waste capsules and dust, ensures fast and orderly pods, and accurately adjusts the capsules.

High precision fiber inspection system

Due to the fast reaction speed, the fiber-optic sensing can realize non-contact detection with high precision, high resolution and good reliability. The device can quickly detect whether the hollow capsules are normally separated during the production process, such as non-normal unseparated hollow capsules, optical fibers. After the system detects the collected data to the filling station and the kicking station, the equipment runs to the filling station. According to the data analysis of the fiber inspection system, the filling station stops adding liquid, and the equipment runs to the kicking station. The abnormal unseparated hollow capsules are removed to ensure the stability of the equipment during the production process.

Main technical parameters

Model No. | NY-600 |

Outout | 36000pcs/hr |

Filling material | Oily liquid, solution/suspension/microemulsion |

Die number | 10 |

Fillable capsule# | 00-4# |

Liquid loading accuracy | ±2% |

Dust collector | Max Pressure 30Kpa,Max Negative Pressure 24Kpa,180m3/h |

Vacuum | -0.02v-0.06Mpa |

Environment | Temperature 20℃, Humidity 40%-55% |

Operating noise | <75DB(A) |

Power supply | 380V/220V 50Hz |

Total power | 6KW |

Air compression | Pressure 0.6-0.7Mpa |

Machine Weight | 1200KG |

Overall dimensions | 1010*880*1700mm |