Pharmaceutical Health Products Food Higher Efficiency Effervescent Tablet and Round Tablet Press Machine

At present, there are two methods to press effervescent tablets in the world: one is to spray magnesium stearate for punching nails in the production process of tablet press. The other is die rotation. The effervescent tablet press produced by our company is the second kind. The machine is capable of rotating the upper and lower dies about 30-40 degrees under the condition of maintaining the pressure (without complete decompression) during the production of tablets. By rotating the upper and lower punches, the fine powder stained on the punches is twisted and pressed onto the tablets, so that the upper and lower dies are in a bright normal state. Therefore, our company has applied for and obtained three product patents on the effervescent tablet press.

Main structure and features:

1. This machine is specially designed for powder with strong viscosity, poor fluidity, easy to be affected by moisture and high humidity. It is an excellent choice for high humidity suppression environment.

2. The equipment is made of stainless steel and meets the requirements of GMP.

3. Frequency conversion speed regulation mode is adopted to adjust the speed for different tablets.

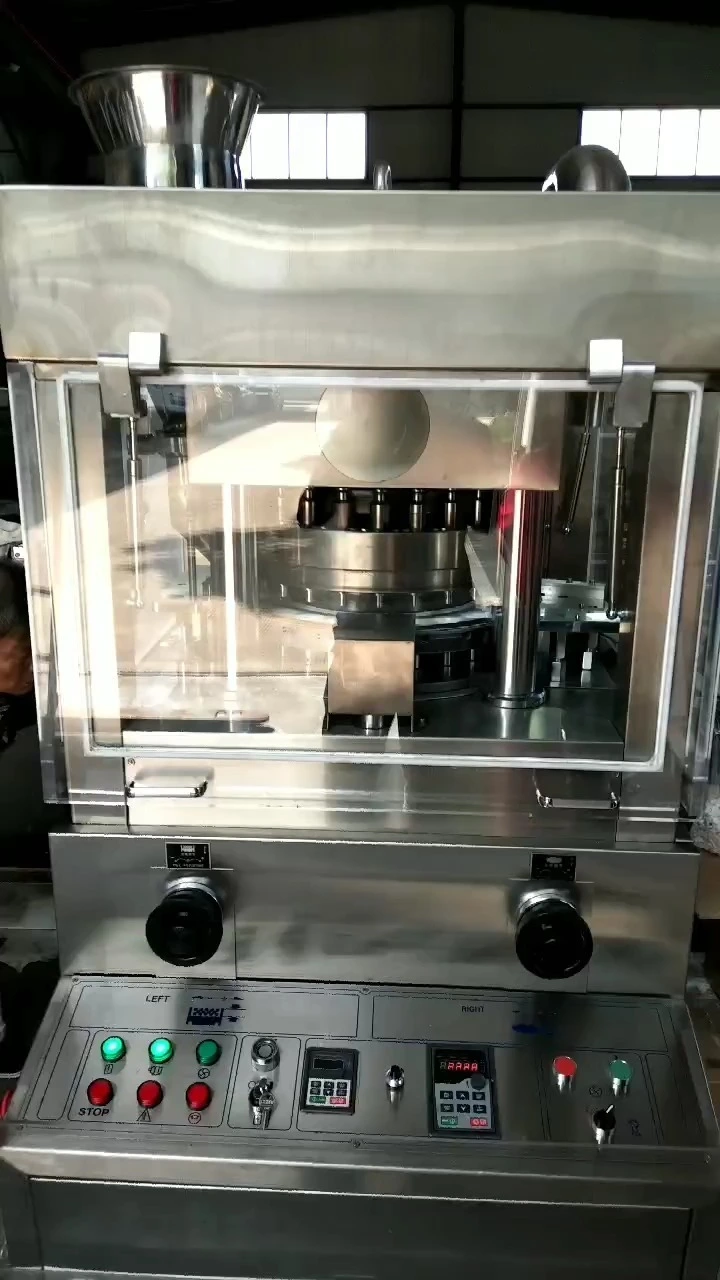

4. The outer cover is fully enclosed, the upper half is closed by the window, and the lower half is surrounded by stainless steel. The contact part of the tablet pressing studio is isolated by a stainless steel cover, which can maintain the surface gloss and prevent cross pollution, meeting the requirements of GMP.

5. It is equipped with transparent glass window, which can clearly observe the pressing state. The window is supported by gas spring. When the door and window are opened, it can directly contact with the interior of the machine, which is convenient for operation and maintenance.

6. This machine is a single press tablet press.

7. The machine adopts hopper and crescent grid feeder as the main feeding device. Pay attention to the gap between the bottom and the turntable when installing and feeding the feeder, which can be adjusted by the strut; A knob is arranged on the top of the hopper frame to adjust the height of the hopper and control the flow of powder. Forced feeding can also be adopted, which is determined according to the characteristics of raw materials of the demander. The machine is equipped with separate high-efficiency dust removal equipment, with high dust collection efficiency to ensure the normal operation of the machine.

8. It is equipped with overload protection device. When the pressure is overloaded, the power-off protection device can stop automatically.

9. The machine complies with jb20020-2004 industry standard and GMP requirements.

This product stands out for its outstanding quality and leading-edge technology, having successfully obtained EU CE certification and UK UKCA certification, while also strictly complying with ISO international standard systems and GMP Good Manufacturing Practice (GMP) certification. The endorsement of these authoritative certifications not only demonstrates that the product meets world-class standards in terms of safety performance, quality control, and production processes, but also reflects our unwavering commitment to excellence in quality.

Since its launch, the product has been successfully supplied to customers in over 100 countries and regions worldwide, serving a wide range of sectors including industrial manufacturing, healthcare, and daily consumer goods. With its stable and reliable performance, superior technical advantages, and comprehensive after-sales service, the product has earned widespread praise and high recognition from customers both at home and abroad. Extensive real-world user feedback and long-term partnerships are a strong testament to its exceptional quality and proven reliability, making it a trusted and dependable choice you can rely on.

Industrial-Grade High Speed Tablet Press Machine

Equipped with an advanced high-speed rotary drive system, this tablet press achieves an output of up to 120,000 tablets per hour, which is 30% higher than that of conventional models in the market. Its continuous operation design and automatic feeding system effectively reduce downtime during production, ensuring a stable and uninterrupted production process for large-scale pharmaceutical, nutraceutical and supplement manufacturers. Whether it is for mass production of vitamin C effervescent pills or regular pharmaceutical tablets, this machine can perfectly meet your high-capacity production needs and help you shorten delivery cycles and seize market opportunities.

Precise control ensures product quality.

Featuring a high-precision pressure control system and an intelligent weight monitoring module, this tablet press ensures that the weight variation of each tablet is within ±0.5% and the hardness is uniformly distributed. The optimized die station design and smooth material feeding channel effectively avoid problems such as tablet cracking, chipping and uneven thickness, which are common in traditional equipment. Every tablet produced meets strict pharmaceutical quality standards, helping you pass product inspection easily and enhance the competitiveness of your products in the global market.

Technical parameters

|

Model |

ZPW-25 |

|

Stations (sets) |

25 |

|

Max. dia. of tablet (mm) |

25 |

|

Max. Pressure (KN) |

80 |

|

Max. Depth of fill (mm) |

80 |

|

Thickness of largest tablet (mm) |

6 |

|

Turret speed (r/min) |

30 |

|

Production capacity (pc/h) |

90000 |

|

Motor (kW) |

5.5 |

|

Overall dimensions(mm) |

1230*950*1670 |

|

Net weight (kg) |

1700 |