High Efficiency Large Capacity WLDH series 500L Ribbon Mixing Machine

features:

1. It is a new type of mixing equipment with high efficiency, high uniformity, high load factor, low energy consumption, low pollution and little destruction to frangible material.

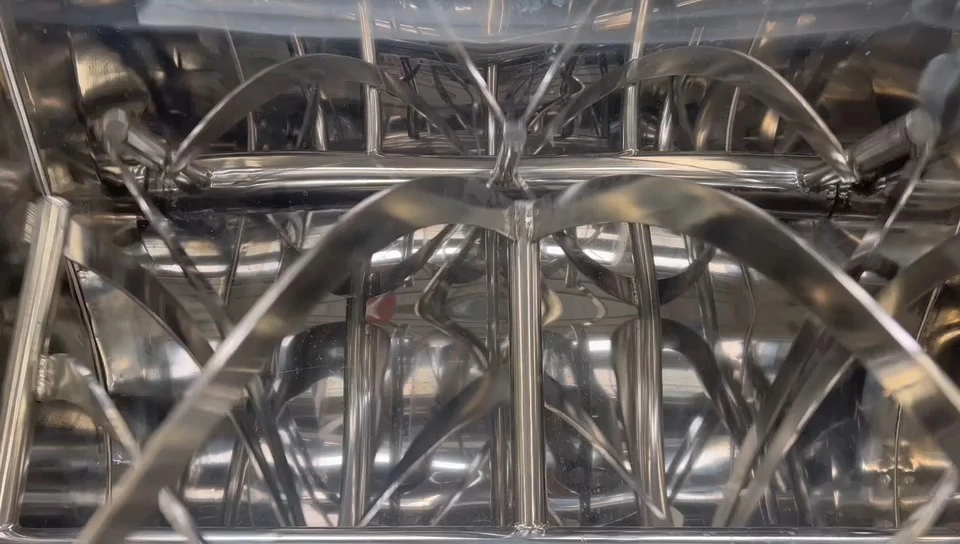

2. The major sections of a mixer are barrel, ribbon agitators, feeding ports, discharging port and driven unit.

3. The ribbon mixer can be equipped with heating or cooling jacket if temperature control is required. We will add spraying or atomizing unit inside the tank.

4. The surface of machine is made of 304 stainless steel material, and the contact powder part can be customized with 316.

Applications:

The ribbon mixer is generally used in the mixing of viscous or adhesive powder material, or the mixing of powder which needs to add liquid, and paste material. Meanwhile, because it is different to clean viscous material, the machine is suitable for the mixing case, where the output is large and there is no need of displacing material variety frequently.

Technical parameters

Items | Parameters | |||

Name | WLDH Model Horizontal Type Ribbon Mixer | |||

Machine volume | 0.5m3/500L | 1m3/1000L | 1.5m3/1500L | 2m3/2000L |

Loading volume | 200-300L | 400-600L | 600-900L | 800-1200L |

Product mesh | 20-500mesh | |||

Mixing motor | 4kw | 7.5kw | 11kw | 18.5 kw |

Weight: | 920kg | 1450kg | 1950kg | 3160kg |

Thickness of barrel | ||||

External frame | Carbon steel / 304 Stainless steel | |||

Feeding way | Auger feeding/manual | |||

Open way | Cylinder auto open cover | |||

Discharge valve | Automatic discharge by cylinder | |||

customized ribbon Mixer

Product details