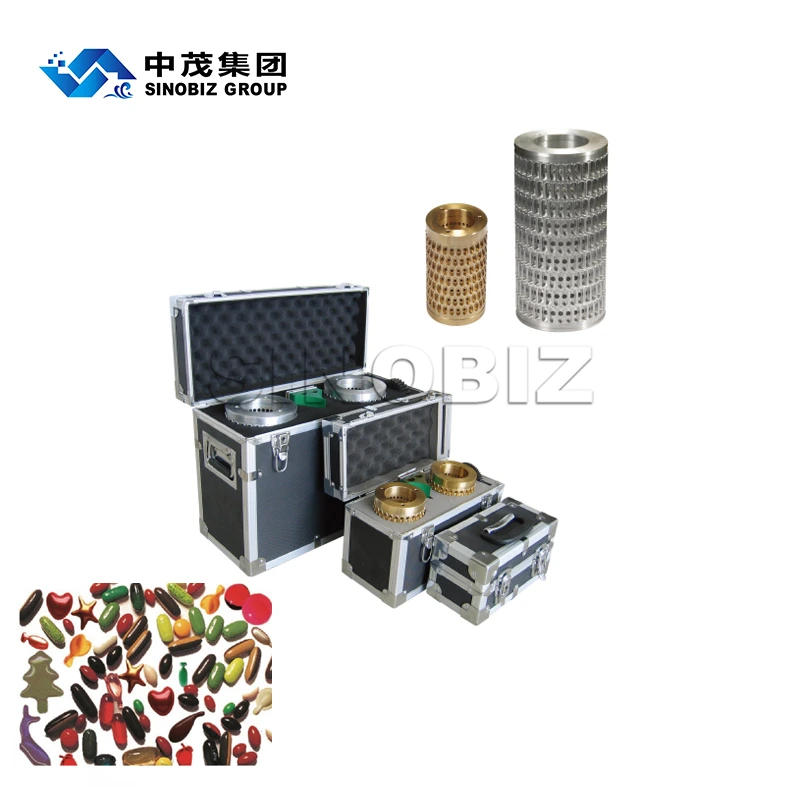

High-Precision Custom Softgel Die Rollers Multi-Spec Soft Capsule Molds and Accessories

softgel die roller

features

Customized Cavity Design:Precisely design the size, shape and arrangement of die roller cavities based on customers' softgel samples, gel properties (e.g., viscosity, ductility) and production process parameters (e.g., drying temperature, speed), fully matching customers' personalized production needs and ensuring the appearance consistency of softgels from the source.

Full Compatibility with Multiple Specifications:Covers mainstream softgel specs (e.g., #2 to #20) and supports multiple cavity shapes (round, oval, etc.), adapting to the production of softgels with different filling volumes (e.g., 0.1ml-1.0ml). It can flexibly switch production needs without additional equipment replacement.

Strong Process Compatibility:Optimize the material and structural design of die rollers according to the characteristics of different gel materials (e.g., gelatin, plant gum) and differences in drying processes, effectively reducing finished product dimension deviation caused by gel shrinkage and process fluctuations, and improving production yield.

Stable Output with High Productivity:With matching die roller speed, a single set of die rollers can achieve stable production capacity of thousands to tens of thousands of capsules per hour. There is no obvious loss of cavity precision during long-term operation, ensuring a continuous and efficient production rhythm.

die roller and products

common softgel shapes and filling quantity

Main technical parameters

Product details