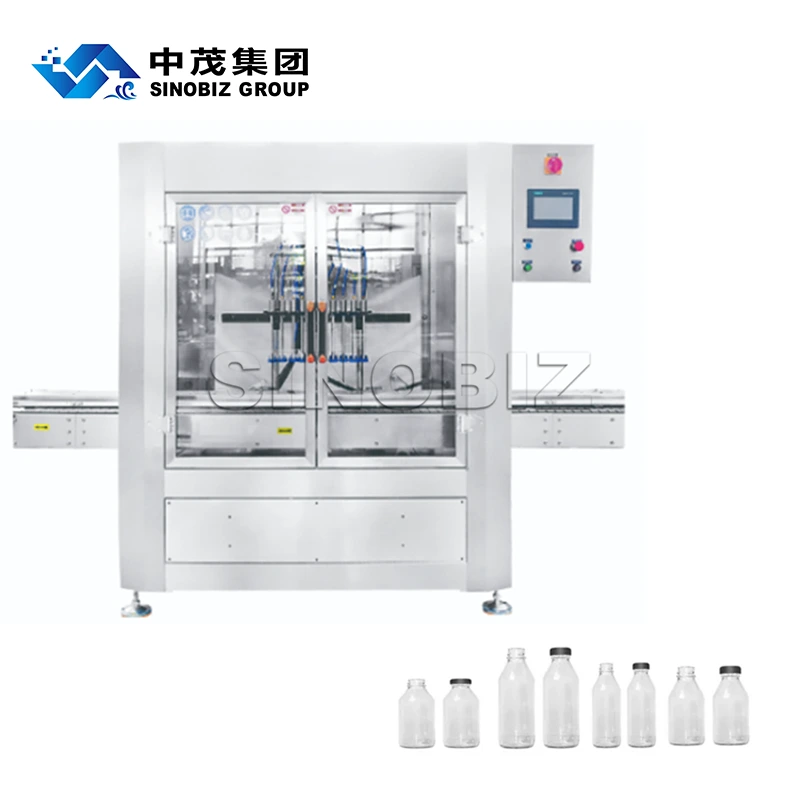

Hot Sale Water-Filled Washing Process Linear Washing Machine

RF-8P/10P Linear Washing Machine filled with water for the water washing process

The RF-8P/10P Linear Washing Machine is an efficient cleaning equipment specially designed for food, daily chemical, canned beverage, condiment and other industries. It is mainly composed of a bottle holding belt, a conveyor belt and a dual water and dual air cleaning structure. It can not only complete container cleaning operations independently but also be used with filling lines, adapting to diverse production needs.

The equipment adopts an automatic cleaning process: containers are transported to the conveyor belt via the bottle holding belt, then flipped into the cleaning system by the bottle holding device. The water washing process is completed by injecting water under pressure through a sanitary pump, and then the spray pipe is inserted into the container for air blowing and rinsing, synchronously realizing the whole process of water washing, gas washing, disinfection, hot and cold cleaning, and drying. It achieves thorough cleaning without dead corners and high cleanliness, fully meeting the strict hygiene standards of various industries.

The product offers two models for selection: RF-8P with a bottle washing capacity of 1500-2000 bottles per hour, a spray pressure of 0.2-0.3mpa, and a power of 1.2kw; RF-10P with a bottle washing capacity of 1800-2500 bottles per hour, a spray pressure of 0.6-0.8mpa, and a power of 2.5kw. It can flexibly adapt to small-batch to medium-batch production scenarios according to production scale. The equipment has strong versatility, suitable for containers of different materials and shapes such as glass bottles and PET plastic cans. Changing bottle types does not require replacing parts, and quick adaptation can be achieved with only simple adjustments. With a simple operation process and convenient maintenance, it is an ideal cleaning equipment for modern canned production enterprises.

features

Dual Water & Dual Air + Water-Filled Washing for Thorough Cleaning Without Dead Corners: Adopts a dual water and dual air cleaning structure combined with a water-filled washing process. After being pressurized by a sanitary pump, the spray pipe is inserted deep into the container for precise flushing, synchronously completing the whole process of water washing, gas washing, disinfection, hot and cold cleaning, and drying. The cleaning coverage is comprehensive without dead corners, and the cleanliness is high, fully meeting the strict hygiene requirements of food, and other industries.

Two Models Available for Diverse Capacity Needs: Two models are offered: RF-8P with a capacity of 1500-2000 bottles per hour and a spray pressure of 0.2-0.3mpa, suitable for small to medium-batch production; RF-10P with a capacity of 1800-2500 bottles per hour and a spray pressure of 0.6-0.8mpa, matching medium-batch production scenarios. It can be flexibly selected according to the enterprise's production scale, featuring strong practicality.

Adaptable to Multiple Scenarios and Containers with Strong Versatility: It can complete cleaning operations independently or be used with filling lines, compatible with containers of different materials and shapes such as glass bottles and PET plastic cans. Changing bottle types does not require replacing parts, and quick adaptation can be achieved with only simple adjustments, greatly improving equipment utilization and reducing production change costs.

machine and products

Features

Easy Operation and Maintenance to Reduce Operating Costs: The equipment's operation process is simple and easy to understand, and ordinary operators can get started without professional training; the core structure is reasonably designed with no complex and vulnerable parts, making daily maintenance convenient and labor-saving; the bottle type switching operation is simple, no additional labor and time costs are required, effectively improving production efficiency.

Multi-Industry Adaptation with Guaranteed Quality and Safety: Complying with the cleaning standards of multiple industries such as food, daily chemical, canned beverage, condiment, etc., it can meet the multiple core needs of container disinfection, cleaning and drying in one stop. It is an ideal cleaning equipment for modern canned production enterprises, with diverse application scenarios and compliance with safety standards.

Main technical parameters

| Model |

RF-8P |

RF-10P |

|

Bottle Washing Capacity |

1500-2000 bottles/h |

1800-2500 bottles/h |

|

Spray Pressure |

0.2-0.3mpa |

0.6-0.8mpa |

|

Power |

1.2kw |

2.5kw |

|

Dimension |

2000*1300*1900mm |

2000*1400*1900mm |

|

Weight |

400kg |

430kg |

Product details